While waiting for Phil …

While waiting for Phil and Sheila, who will pay us a visit next summer, I realised I will run out of porter well ahead of their visit. This is unheard of, as Phil is a great lover of porter.

I immediately started planning making a new one. Porter is a dark style, top fermented beer developed in London long time ago. The name was first recorded in the 18th century, and is thought to come from its popularity with street and river porters, who carried objects for others.

I have made this beer several times and have a real good recipe. Making the beer consist of several steps.

- Order, pay and collect yeast, malted barley and hops

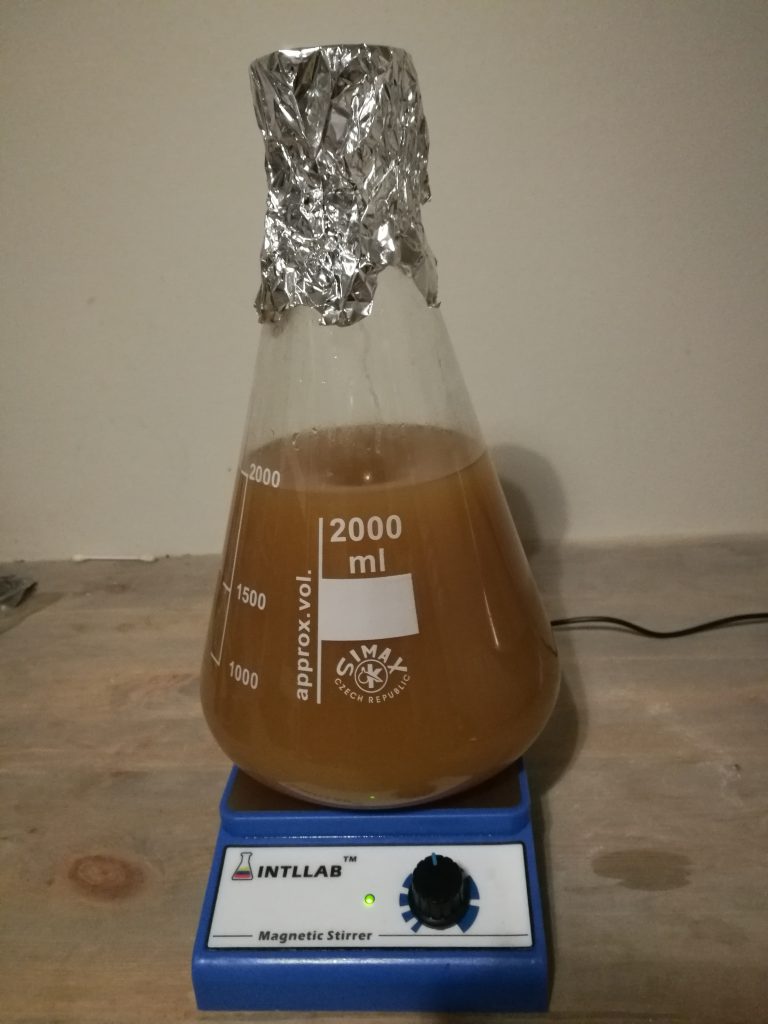

- Make yeast starter and harvest yeast

- Make the wort from malted barley and water, called the mashing process

- Boil the wort adding hops for both bitterness and flavouring

- Add yeast nutrition

- Cool down wort and add the yeast

- Let it ferment

- Clearance and bottling

Making the yeast starter has to be done at least 2 days ahead of making the wort. This is because the yeast cells has to populate until a number that is sufficient to eat the sugar in the sweet wort and produce co2 and alcohol. When you know the sweetness of the wort you can calculate how many yeast cells are necessary to produce the alcohol of a certain type of beer. It is a common idiom in beer brewing, that man makes the wort, yeast makes the beer.

Wort is then made by soaking malted barley in water for a certain time under a certain temperature. The temperature determines how much sugar is taken out. The wort is at last sparged with water to get all dissolved sugar out.

After the mash process, the wort is boiled for 60 to 90 minutes, depending of barley types, hops added at certain intervals depending if it is for bitterness or for flavouring.

The boiled wort the has to be rapidly cooled down to around 18 degrees, poured into a suitable fermentation vessel, and yeast added to it. Fermentation will go along for 10 to 14 days until the ready beer can be cleared and bottled. Co2 must be added before bottleds are capped, or sugar added for a secondary fermentation on the bottles.

In the small video below, you will see that the yeast is living, vigorously swimming around eating sugar, producing alcohol, Co2 and heat. Temperature in the room is 18 degrees, while the liquid inside the vessel is 24.

The porter will be bottled after we get back from the cruise and left to mature for a long time and will be ready for consumption well ahead of the planned visit next summer, unless visits from bad friends.